APPLICATION

INSTRATUCTIONS FOR APPLICATION STEO BY STEP

Clean the surface very well with pure alcohol or clean acetone (without oil). No sticker can be applied to a dirty surface. The surface must be free from oils, dust, sand, etc. Especially on a new boat, cleaning should be meticulous. New boats may have wax residues from the mold. Let it dry well.

Spread the pieces in their positions and secure them with masking tape after aligning them correctly. Proper alignment is important for the final visual result in the subsequent joints.

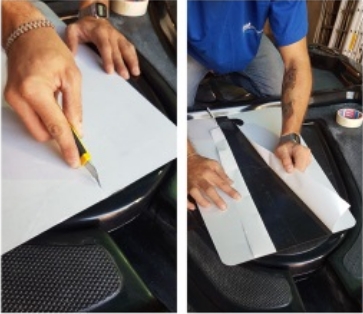

Turn the sheet upside down and lightly score the silicone paper with a blade until it opens in two parts. Peel off and fold the silicone paper for 5 points on each side at the point where you scored it.

Turn the sheet on the right side and, once you find the sticking point, press firmly in the middle where the silicone paper is peeled off. Due to the strong adhesive it has, make sure you are at the right spot before sticking. If it sticks crookedly, do not attempt to peel it off. It should not stretch at all during sticking.

Continue by slowly pulling the silicone paper while simultaneously pressing the sheet with your hand or a plastic spatula. The pressure must be applied meticulously so that, apart from good adhesion, there are no spots where air, water, or dust could penetrate in the future.

At the end, very good pressing with a roller and around the perimeter of the sheet. Good pressure is very important. There should be no gap or trapped air inside the material. If there is any trapped air, remove it with a syringe.

During the application and for the next 48 hours, until the glue is polymerized, the temperature must be over 17°C.

Otherwise the foam adhesion may be detached.